At FRIGERI we are strongly determined to become a better company. To excel among the excellent.

We don’t aim to be better than others. We just want to be better ourselves, to become every day more expert and more able at doing our job.

This is why FRIGERI invests between 2.5 and 5% of its annual turnover in Research & Development.

FRIGERI, despite being a small company, is a high-level job shop and a lean, well-organised R&D lab.

What drives and motivates our research is not so much the speed of changes in today’s global economy, nor the awareness, that in FRIGERI is full and deep, of its structural complexity and high selectivity. It is rather our unquenchable thirst for knowledge and our individual and collective drive to find ways and instruments for doing what we do better, and so give greater value to our Customers.

All this means for us not just exploring exciting new technological possibilities, but above all redefining what is to be considered technologically possible.

FRIGERI’s operational R&D structure uses:

- internal resources;

- external specialists and consultants;

- relationships and collaboration with universities and research institutes.

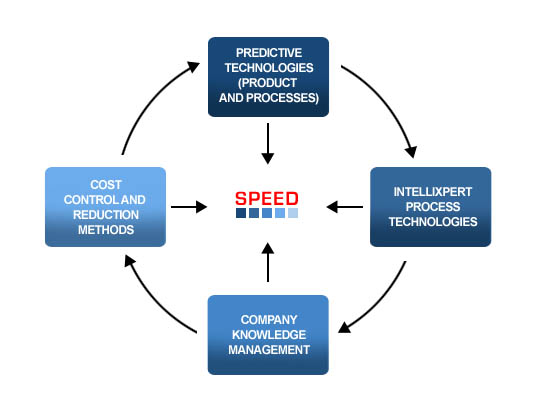

FRIGERI’s R&D work follows four main lines:

- predictive technologies (product and processes);

- intellixpert process technologies;

- company knowledge management;

- cost control and reduction methods.

The crossroads and the point where these lines meet and fuse together is, of course, SPEED.

What is SPEED?

The SPEED (Self-driven Production Expert Environment for Dies) project is the magnum opus and the pride of FRIGERI.

FRIGERI’s R&D has been working on it since October 2008, after 4 years of research and preparation. SPEED aims to create an entire, hardware and software integrated production system that is intelligent and self-moving, able to design, manufacture and assemble dies for sheet metal in a markedly de-skilled environment with little or no need for expert human intervention.

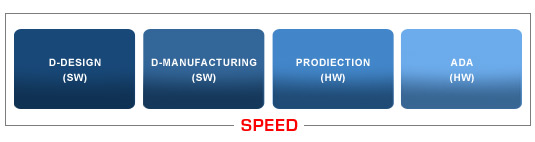

Briefly, SPEED consists of four subsystems:

Both the D-DESIGN sw module (with 2 submodules, for automatic handling of stamping layout planning and die design) and the D-MANUFACTURING sw module, that automatically handles milling, turning, drilling, EDMW and grinding) are based on a specially created proprietary AI code, AFR technologies and hybrid inferential routines.

The PRODIECTION hw module consists of an automatic, selective, modular and flexible production line in which are integrated handling, manipulating and adjustment devices for materials, semi-finished and finished products and measuring stations with a two-way interface.

The ADA (Automatic Die Assembly) hw module consists of a plant for the assembling and automatic coupling of dies and for any reworking of parts that do not conform.

The most important thing about SPEED, which the FRIGERI management wanted as the basis of the entire project, is that the core knowledge of such a complex process as the design and manufacturing of stamping dies does not depend on people, but is contained in and implemented by the D-DESIGN and D-MANUFACTURING sw modules. These are intellixpert agents: intelligent because they can autonomously manage specific process with human style problem-solving capacities and expert because they contain expert knowledge.

Thus, thanks to SPEED, operational know-how does not belong to those who apply it but, like the factory and its production machinery, belongs to the company and remains under the company’s full and unconditional control.

SPEED attack

1) SPEED is an entire production environment, not a single product or process. It can be infinitely grown and expanded, and is thus a TOTAL competitive weapon.

2) SPEED was conceived to contain all the specific predictive, productive and operational knowledge available. Methods of inputting new knowledge, necessary to continuously regenerating the subsystems and maintaining their vitality, will be integrated into the same environment.

3) SPEED is designed to implement the core knowledge it contains (Die Design&Manufacturing) AUTONOMOUSLY and WITHOUT HUMAN INTERVENTION, a method quite different from that of traditional toolmakers. Supporting know-how, currently managed in part by human intervention, will be progressively transferred to and operated directly by SPEED.

4) SPEED will allow progressive and complete transfer of knowledge and fundamental competences from men to intelligent systems, thus guaranteeing the immortality and inaccessibility of company know-how in the very long term.

5) SPEED is a production environment that cannot be imitated. Competitors, particularly those that prey on others, may be able, with great effort and great approximation, to imitate and copy the products of SPEED but they will not be able to replicate the entire environment that is always in motion and self-moving. The competitive advantage is thus destined to become permanent and unbeatable.

SPEED in numbers

1) ANNUAL PRODUCTION CAPACITY: estimated at at least €20 million when fully operational, with the possibility of expansion by adding new production lines.

2) PERSONNEL: as currently configured, SPEED needs a core team of 8 to 10 people.

3) PRODUCTION COST: a set of dies produced by SPEED when fully operational will cost less than the same set produced by the cheapest diemaker on earth.

4) PRODUCT QUALIFICATION: in the toolmaking sector, dies are considered prototypes needing extenuating, long (even 3-4 weeks) and costly testing on Customer presses before mass production can be safely and efficiently started. SPEED, which operates using the entire available knowledge base and has decision-making capacity and multiple operativity, will allow the first SET&PRESS dies to be produced. Delivery of dies and production startup will become synonymous for SPEED products.

5) LEADTIME: in the startup phase alone, SPEED will halve the lead times for homogeneous die production: the current 3 months for delivery will, with SPEED, become 1.5 months from Customer order, with the advantages in points 3) and 4).