Being a toolmaker for someone is a somewhat strange job. We agree.

Below you will find some true stories as a proof of it.

Story #1

A milling machine operator checks a measurement on his PC. He has a moment of doubt. He sends an e-mail to the designer asking for help and goes to the Design Office.

“I’m about to start work on model X, could you check a measurement for me?” he asks.

The designer asks him to wait a moment, and opens the CTS (Company Time Statement, a document updated every minute that allows staff to verify their time against the target time allotted for each job) on his computer, to see how much time he has available.

“I’m already at the limit of my time budget,” replies the designer, “if I checked the measurement I’d exceed it. I can’t. I’m sorry”

The operator returns glumly to his station.

Story #2

After about 2,500 hours of designing, manufacturing, assembling and alpha and beta testing of the tool set for a cooking top in two different materials and 14 versions, at last the great day arrived: the final test in front of the customer was set for 10.30.

At eight the Frigeri senior tester, Jet, started up the pre-test behind closed doors. A shock was in store for him. The pressing, which had been fine a few days earlier, now showed tiny undulations and imperfections. The customer would never accept it!

Jet checked all the parameters on the test card again and restarted the test. It was no good, the defects were still there. No amount of checking, stripping down, reassembling, lubricating and retesting made any difference. The pressing just wasn’t right.

By now it was ten o’clock and the customer would soon arrive for the decisive test. It had to be put right and quickly. But how?

Suddenly, Jet sprinted for the changing room, returned to the press and restarted the test. We saw him putting drops of something here and there on the die between movements of the press. Was he resorting in desperation to some magic potion?

At that moment the customer delegation arrived and headed inexorably for the press.

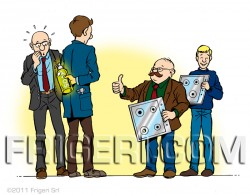

Jet turned to the delegation and nodded a greeting. The delegation bowed in return. Jet started up the press. He took a pressing, examined it, cleaned it and passed it to the customer’s quality inspector, who examined it minutely. He took it under a light, scrutinised every millimetre, back and front, at if it were a valuable archaeological find.

Long minutes passed. The Frigeri team held its breath.

Finally the quality inspector looked up towards Jet. He pointed to the pressing. And gave a thumbs up sign. Everything was OK!

I went up to Jet and asked him under my breath: ”What the hell were those drops you used?”

Jet looked around to make sure nobody was within earshot. He replied in a whisper: “Liquid soap”.

Story #3

When we first introduced the Company Time Statement, we expected a great deal from it: more individual awareness of planned times and costs, less difference between actual time taken and planned time, more incentives for proactive attitudes and respect of company procedures. What we hadn’t expected and came as a real surprise was that the CTS led even the most unsuspected staff members into a minute analysis of their work to identify critical stages that would risk exceeding the time budget.

I had an unexpected but gratifying example one day when, as system supervisor, I received a message from an operator who was not only rather taciturn and not given to writing such messages, especially such a long one, but was also quite new to written analyses of any kind. The mail read:

“In a few moments I will be opening session X, job number Y. I will probably exceed the time budget allotted. It does not seem to take account of the need to bring structure Z, where about an hour ago a test revealed faults, back into conformity. The time budget also seems not to take account of the need to level off the bush-holder hubs, which have about 9mm more extra metal with respect to the project file. Lastly I would like to say that I would find it extremely useful if in the process plans we could insert separate headings for tooling up and preparation of the component and tooling down and final cleaning, to keep the times under better control. But I’ll leave that to you. Thanks.”

You’ll perhaps understand better why I was so surprised if I tell you that the excess time my friend was so worried about, and quite rightly, turned out to be about 25 minutes in a total of more than 14 hours’ job time!

Story #4

We introduced the stamping simulation software into the company back in 2002. At first it was far from easy to use: it was a powerful instrument we had to learn to control and undeniably complicated, though this we felt was a guarantee of good results. Then there was also the scornful attitude of the staff towards this virtual and arrogant know-all.

The height of their disdain was reserved for the time it took to complete simulations, which they felt was interminable (in stark contrast with their furious industriousness as traditional die makers). And to be frank, it did sometimes overstep the deadline for starting production of the project.

It was perhaps because of this that at the time a tasty anecdote made its rounds of the company. We never did manage to find out the author:

“It took four long, hard months to design, manufacture and assemble the die, then test it, first with the alpha cycle then with the beta cycle, and finally carry out a scrupulous debugging. At last it was ready to be delivered to the customer. The truck arrived: the die was packed, made safe, all the conformity documents were attached, it was balanced carefully in the loading bay, loaded, settled, and given a farewell pat. The truck started up, the driver waved, the gate opened. The truck started to drive off. At that moment, the door of the Engineering Department burst open. A man rushed out in a panic and hurtled towards the truck, shouting at the top of his voice: ‘Stop the truck, stop the truck! The simulator says the part’s going to break!”

Story #5

In 1997 we were in Shanghai, China, to test and start up the first set of dies we had ever exported to that industrious nation, which was just beginning its industrial explosion. To be honest it was one of our first experiences as global diemakers, and we were real provincials. But we were staying in a magnificent international hotel, with other delegations of technicians from various European companies, and the sight of a real metropolis that was growing before our eyes, day and night, had us wide-eyed.

The evening of the first day of testing we were exhausted but highly motivated to satisfy all our Chinese customer’s expectations. We joined the other European delegations, who knew more about China than we did, for a dinner of local specialities. The food was excellent, and so were our appetites. Fellow feeling with the other technicians and managers completed the cordial atmosphere.

At a certain point, Louis, one of our technicians, spotted a platter bearing a magnificent but still intact roast, rather long in shape, surrounded by colourful vegetables. Louis, who was a hearty eater, as he’d already demonstrated, helped himself to a sizeable portion and tucked in with gusto.

“Really good!” he observed.

Then, as he raised his eyes from his plate, he noticed everyone was staring at him. Some were suppressing smiles.

Louis was puzzled. The man next to him whispered in his ear:

“Enjoy the roast, Louis?”

Louis nodded.

“Know what it was, Louis?”

Louis shook his head.

“You’ve just eaten a horse’s dick.”

Everyone burst out laughing. And Louis, once he’d got over the shock, joined in.