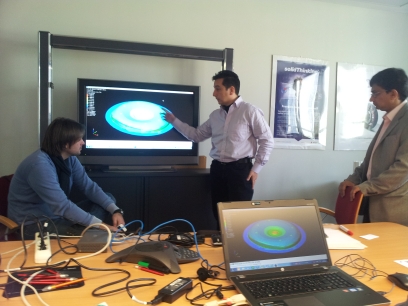

Turin, Italy, 22 March 2012. A Frigeri delegation, guided by Frigeri Vice-President Roberto Di Zitti, has met the metalforming division of Altair Engineering, the italian office of Altair. In addition to Altair Engineering engineers, the meeting was attended by Subir Roy, Altair Director of Industry Solutions, and Erwan Beauchesne, Altair Manufacturing Technology Manager.

Since 2002, when Frigeri, among the very few toolmaking companies in the global market of home appliances and as one of the front runners of the home-appliances focused stamping simulation in Italy, introduced inside the die design process Altair HyperForm, the comprehensive FE-based sheet metal forming simulation framework, the relationships and the experiences and best practices exchanges between Frigeri engineers and Altair R&D, ever solidly founded on quickly targeting real shop floor issues and needs, have been strengthening and growing year after year.

The meeting was the opportunity to merge the sum and the distillate of Frigeri’s ten years of experience as an Hyperform user with the competence and the passion of the Altair Product Development Team and to share them into a renewed long-term market perspective.

“Frigeri is committed to deliver all its Customers,” said Roberto Di Zitti “perfect dies in a fraction of the present time and at a fraction of the present cost. This commitment cannot ignore, in today’s tough global market, the application and intensive use of a reliable, efficient and effective Simulation-driven Design Technology. Stamping simulation is a key technology for the competitiveness of a global toolmaker. For us, stamping simulation means Altair and Hyperform.”

During the meeting have been discussed matters like trim line optimization, adaptivity, multistep management, tool motion during a forming calculation, management of the variable motion laws and strengths, friction values, material FLCs, Lankford coefficients.

Finally, Frigeri has presented three case studies, that have been largely reviewed and discussed under the point of view of the correlation of the simulated models vs the physical models.

“The meeting,“ said Emanuele Dealessi, Altair Enginering Sales Account Manager “has been very helpful for Altair, in order to develop a better software and more responsive to the customer needs. The relationship existing between Frigeri and Altair is the striking example of what we mean when we aim to be partner of our customers and not simple suppliers.”

“I hope,” concluded Roberto Di Zitti “that such a productive and really far-sighted and open-minded meeting model, with its related time investment, could replicate itself into new and increasingly efficient and productive forms. What we ask to Altair is “simply” to develop more and more Hyperform so to make it a perfect, easy, user friendly stamping prediction machine.”

Product Catalogue

Product Catalogue