Simulation Driven Design: The Get It Right The First Time Challenge

There is no doubt that stamping simulation, also called virtual press testing or metalforming simulation, is the closest thing an engineer has today to a crystal ball in terms of understanding and predicting metal stamping die behaviour within the confines of their operating environment.

As a cornerstone of our design process, over the years we have been exploring, developing and integrating methodologies and software tools to set up and implement a simulation driven design environment in which CAE and CAD can be deployed in parallel and stamping simulation results drive changes in the die design.

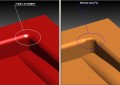

CAE, using up-to-date intelligent technology, drives in predicting the optimum part geometry and stamping scenario, allowing our CAD designers to identify, test and validate, before design release and “before the first-swarf-fall”, the best tool set configuration faster and in a cost-saving way for outstanding final tool performance.

Product Simulation

First Attempt

> Solid Modeling

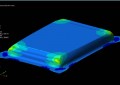

> Simulation Setup

> Run and Prediction

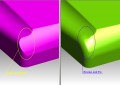

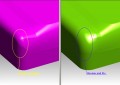

> Review and Fix

Final Attempt

> Solid Modeling

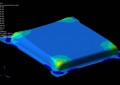

> Simulation Setup

Product Catalogue

Product Catalogue