Simulation Driven Design: Answering Requests For Quotation

Since, from a mere structural point of view, no substantial difference exists between our pre-contractual and post-contractual engineering process management, both in terms of signalling response and in terms of commitment towards, respectively, the virtual or actual Client, our Simulation Driven Design Environment give us a competitive edge when it comes to answering Request For Quotation (RFQs).

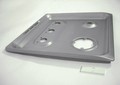

It allows our designers to assess early part geometry formability and manufacturability, address and solve feasibility issues&criticalties, find the best business option by verifying and validating multiple stamping scenarios and finally answer the Client’s RFQ with an integrated engineering output that, having nothing of the ordinary rough estimates of the common toolmaker, is more comparable to a preliminary project, just ready to be launched at a touch of the Client towards final success.

Quotation Process

> Stamping Simulation – One Step Analysis

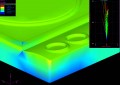

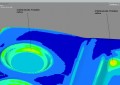

> Stamping Simulation – Incremental Analysis

> Custom Applications

> Stamping Layout Optimization

> Die Configuration Optimization

> Part Producibility Optimization – Part Final Geometry and Shape Prediction

Product Catalogue

Product Catalogue